Team Rollon

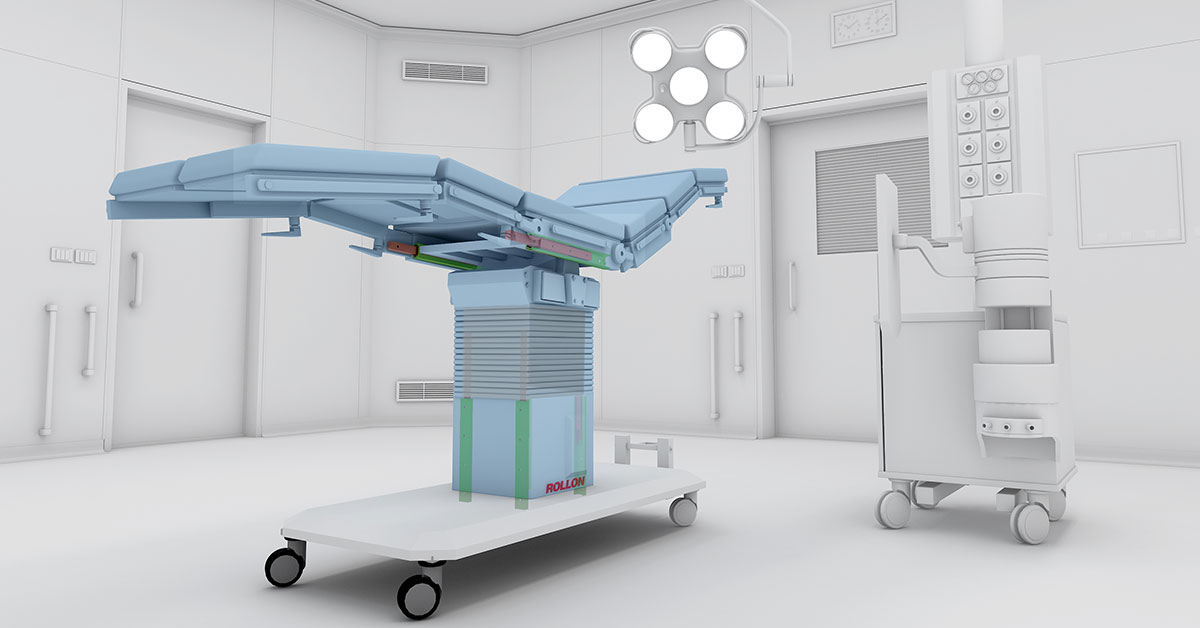

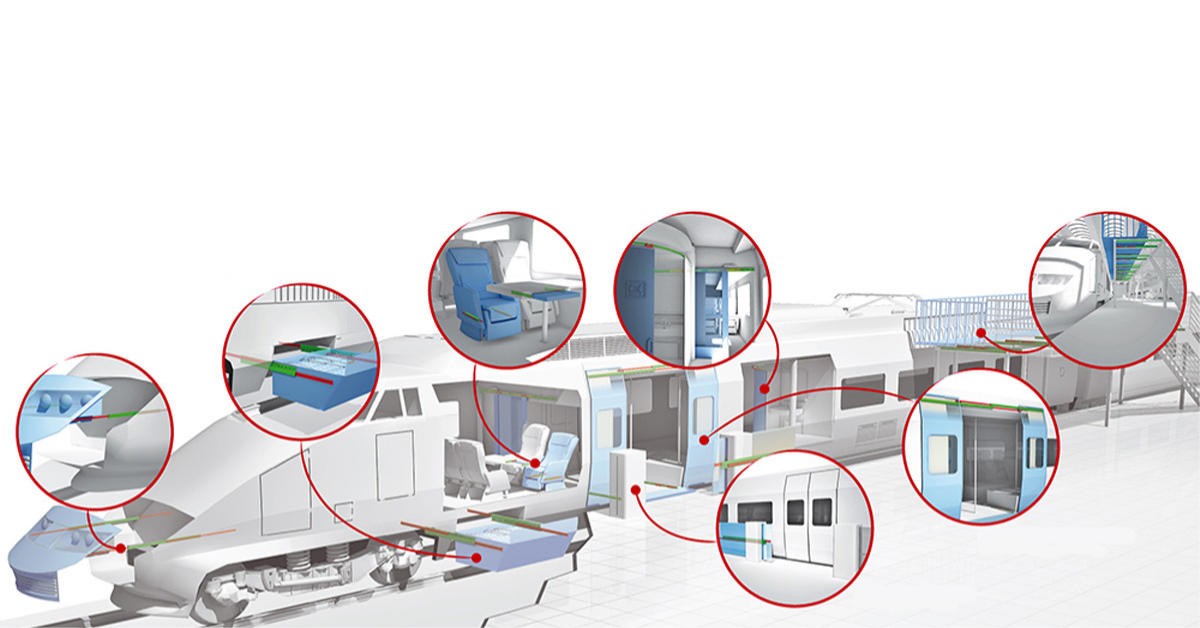

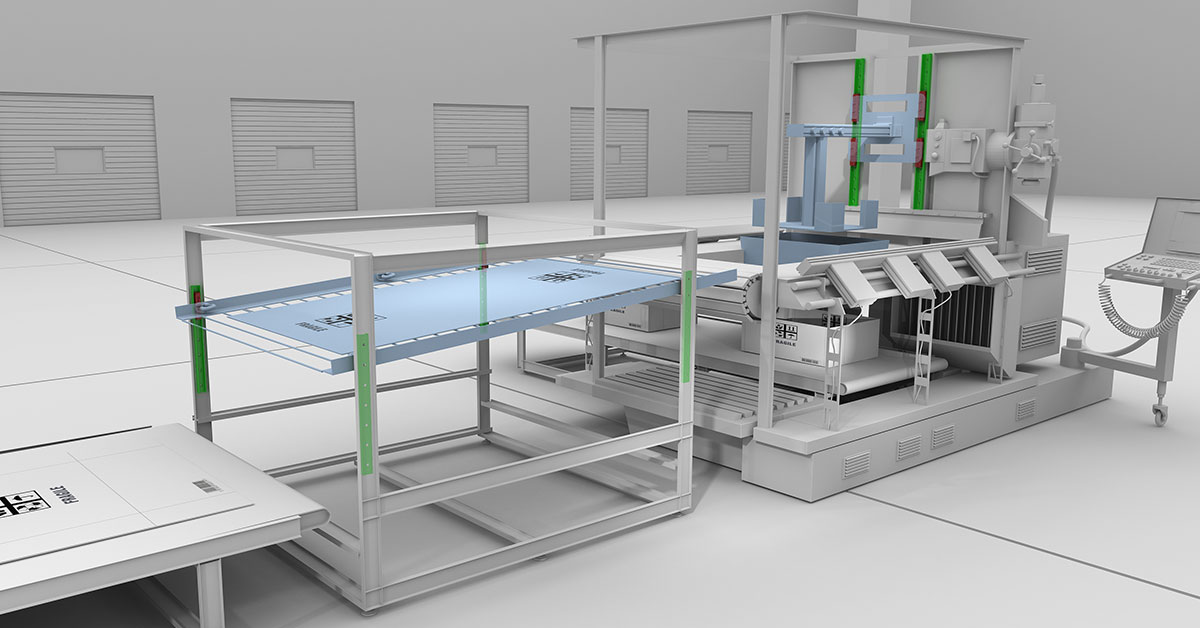

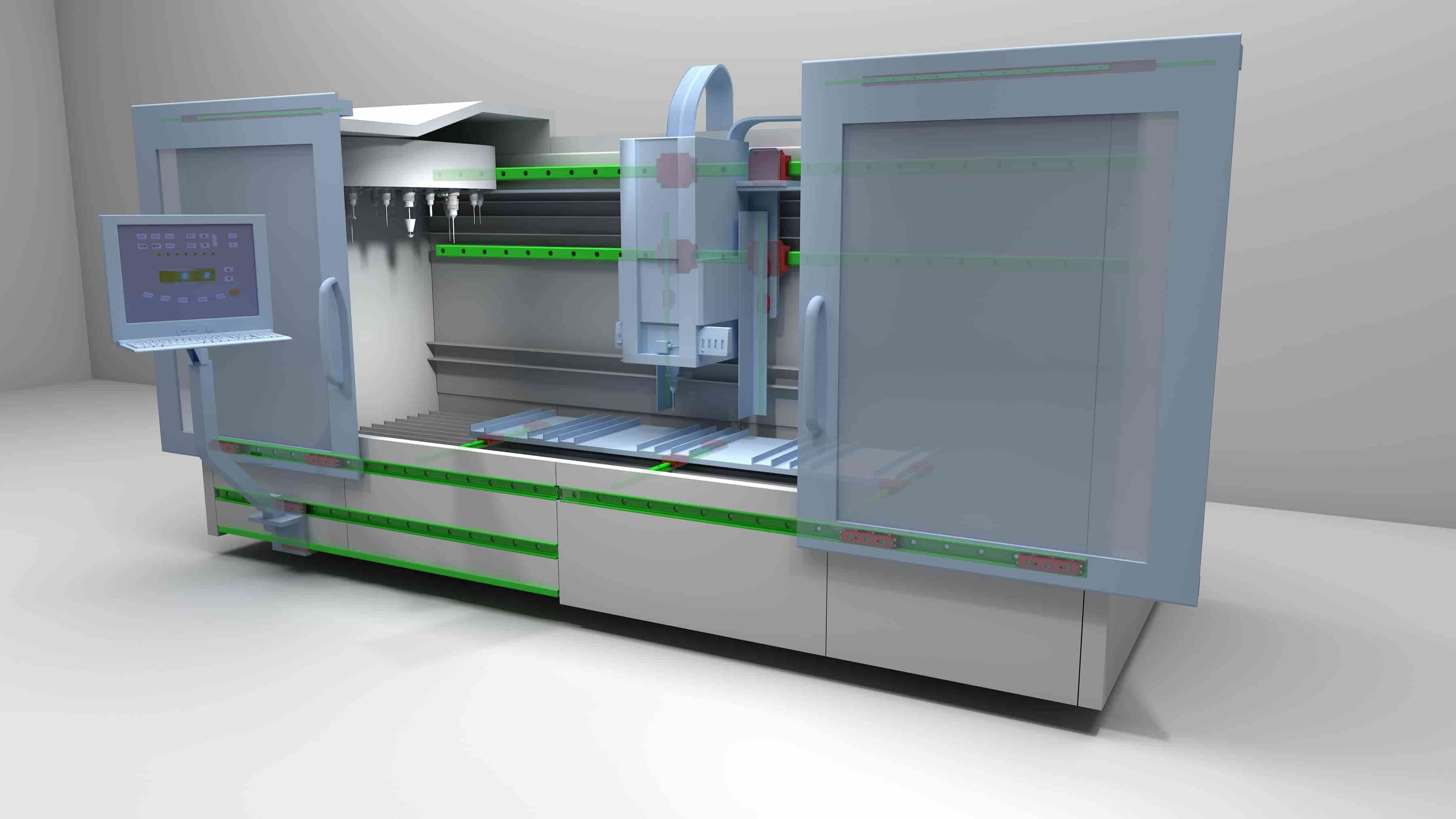

Rollon is a leading international provider of linear motion solutions, i.e. linear and telescopic guides, actuators and complex gantry systems. The way we work is very simple: we listen to our partners, capture their needs, requirements, challenges and concerns and work closely with them to choose the best solution for their next motion application. The efficiency and performance of each application is always the goal. But what other variables should be taken into consideration so that production efficiency does not overshadow constructive, economic and maintenance efficiency? We have learned to answer these questions and more. Thanks to 45 years of experience in the market, we gained the skills and know-how to pick up on things that an be the key to every designer, but may appear nuances to the unexperienced eye.