Medical imaging, Rollon rails for safe and accurate applications

17 Feb, 2022

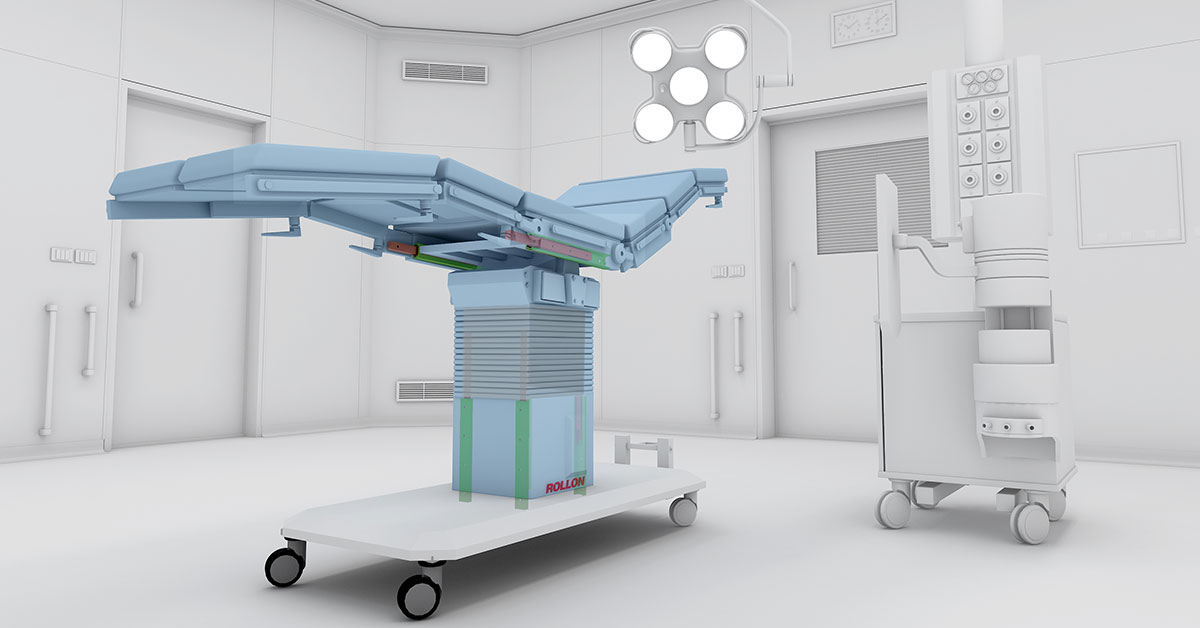

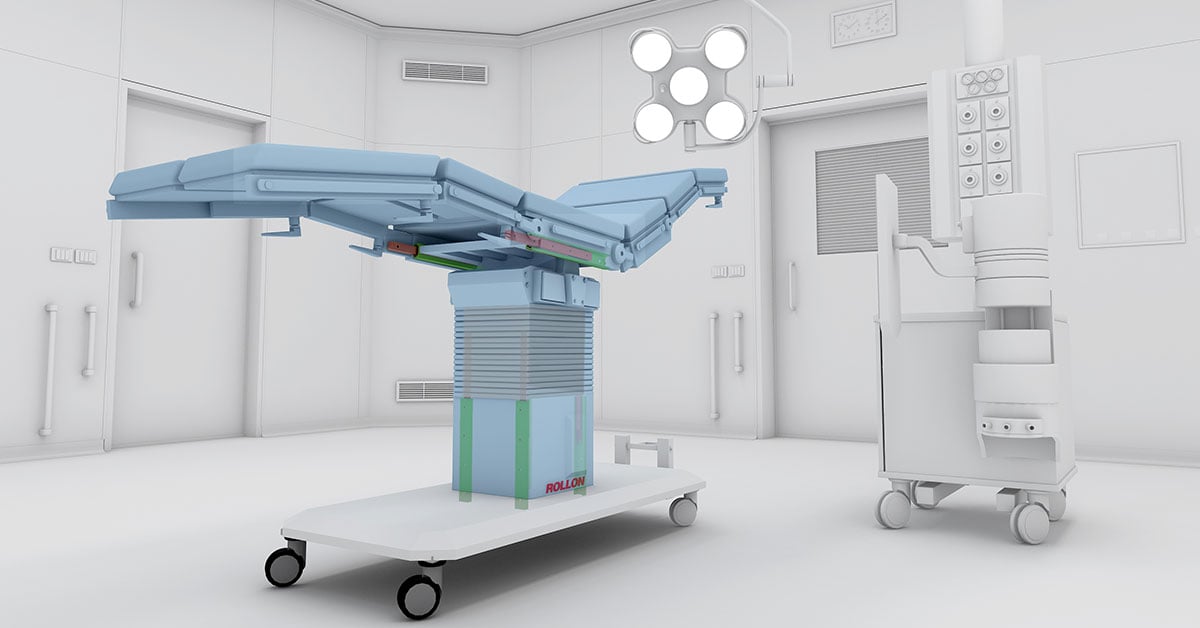

Rollon linear rails provide smooth, quiet movement of beds in medical imaging applications and auxiliary motion axes. Accuracy of motion, patient comfort and handling of heavy weights are the pluses of linear motion solutions.

Linear guides in the healthehe medical sector

Medical imaging systems contain so many high-tech electronic elements that it is all too easy to overlook the mechanical components that contribute to the success or failure of these systems in the field. Consider linear rails, for example. They are found on a variety of imaging systems, from traditional X-ray machines to advanced systems such as magnetic resonance imaging (MRI), computed tomography (CT), and positron emission tomography (PET).

Typically, rails are used to move and support motorized beds that position patients under the scanning elements of the system, although sometimes they are also used for auxiliary motion axes.

Operating a motorized bed is a seemingly simple task, but it's also crucial. If these linear rails fail, they can put even the most advanced imaging system out of commission. Failure in these medical imaging applications usually occurs when the rails are not strong enough to handle the heavy loads associated with moving patient beds. With these loads, which usually exceed 1,300 kg, the rolling elements installed in the rails can easily become misaligned and wear out prematurely.

However, there is another aspect, often underestimated, that decrees success in medical imaging applications; bearings must run quietly and smoothly, not only for image quality, but also to ensure proper patient comfort. Research has shown that mechanical noise negatively affects patients, increasing their anxiety levels and potentially triggering panic attacks in extreme cases. Misalignment can also play a role here, making the bearings noisy and reducing their rolling capacity.

Compact Rail linear guides: silent and reliable

Rollon Corp. has developed a variety of different linear rails with roller bearings over the years that help solve linear motion problems that can plague medical imaging machines.

In the Compact Rail, the slider moves on large ball bearings inside profiled rails. This arrangement offers three key advantages in medical imaging applications.

- Ball bearings, larger than in other configurations, create an efficient and durable system. The largest Compact Rail rails measure less than 6.35 inches high and can support a maximum load of 1,540 pounds, more than enough to accommodate a motorized bed rated for about 230 pounds.

- The Compact Rail is a rail that can easily handle misalignment in the sense of parallelism and coplanarity. The rail profiles are specially designed to allow axial freedom of the bearings within the tracks.

When building imaging machines, this ability to handle misalignment greatly simplifies mounting surface preparation and rail installation. Throughout the life of the machine, misalignment tolerance helps reduce bearing wear. Lastly, the bearings mounted on Compact Rails are quiet compared to systems that rely on recirculating ball bearings. In tests conducted by Rollon, Compact Rail sliders with ground tracks generated less than 70 db of noise when traveling at 2 m/s with a load of 4,000 N. A comparable recirculating ball bearing operating under the same conditions generated 86 db.

Telescopic guides for full-extension applications

Rollon Telescopic rails, with partial and full extension and extremely low deflection, feature a robust design and ball cage movement. The largest telescoping rails offer strokes of more than 1.98 meters in one direction, or 3.96 meters in models with extensions at both ends connected by a fixed intermediate element. Constructed of hardened or cold-rolled steel, these rails can withstand heavy loads even in cantilevered configurations with very little flexing.

To give an example of a telescopic rail that is often used in medical imaging applications, Rollon's ASN63-1970 rail can support a load of more than 4,500 kg with negligible deflection even when extended by 50% of its total length to its full 1-meter stroke. The combined use of two of these partial extension telescopic rails doubles the load capacity to 9,000 kg.

Full extension telescopic rails are an option that allows for even greater extensions. Rollon's DMS63-2210 track, for example, has a fixed length of 220 centimeters and a total stroke of 226. When fully extended, a pair of these telescopic rails can support a 900-pound load with a maximum deflection of 1.3 inches.

Telescopic rails are most often used in applications that require low-profile, simple and economical support for beds with cantilevered configurations or imaging tables.

For more information on the Rollon's Rails

Leave a comment

Latest articles

Topics

Stai utilizzando la guida giusta per i tuoi progetti?

Rollon presenta la nuova generazione delle proprie guide lineari a cuscinetti con una capacità unica di gestire il disallineamento delle superfici di montaggio.

GUARDA IL WEBINAR