The US Special Vehicles Company (SPEVCO), based in Pfafftown, North Carolina, has established itself as an innovative company, with some strong problem solving skills, in the specialty vehicle industry. In fact, it's not uncommon to see their installations during big-name events across the US, whether it's Speed TV's led truck for the NASCAR championships, the Dunkin' Donuts tasting truck or even the John Frieda mobile hair salon.

Mobile medical units by SPEVCO

In response to the aftermath of Hurricane Katrina, SPEVCO even began production of mobile medical units commissioned by FEMA, the Federal Emergency Management Agency, and destined for the Gulf Coast. More recently, SPEVCO has been commissioned by the State of Minnesota to design and build a 16-meter long mobile hospital unit equipped with three expandable modules, called "pods" in jargon.

From converting vehicles for advertising purposes for prestigious brands during NASCAR races, to providing mobile medical facilities for FEMA, SPEVCO has specialized in space planning and load design to significantly increase the size and capacity of the customer's vehicle.

As Luigi Utili, mechanical engineer at SPEVCO, says, the company has gained extraordinary expertise in the development of pods, custom expandable sections of trucks that can quickly increase the floor area regardless of the type of project.

SPEVCO chooses Rollon Compact Rails

Luigi explains:

"For the large pods, we developed an ad hoc in-house solution based on a hydraulic system, but since one of the sections of this vehicle only measured 3x1 m, we replaced this system with more cost-effective linear rails to handle the movement of the pod."

"The section contains several heavy medicine cabinets, as well as coolers and analytical instrumentation, so the rails must be able to support about 900 pounds. In addition to being uneconomical in terms of production, the placement of the custom hydraulic system would have compromised the rigidity of the structure."

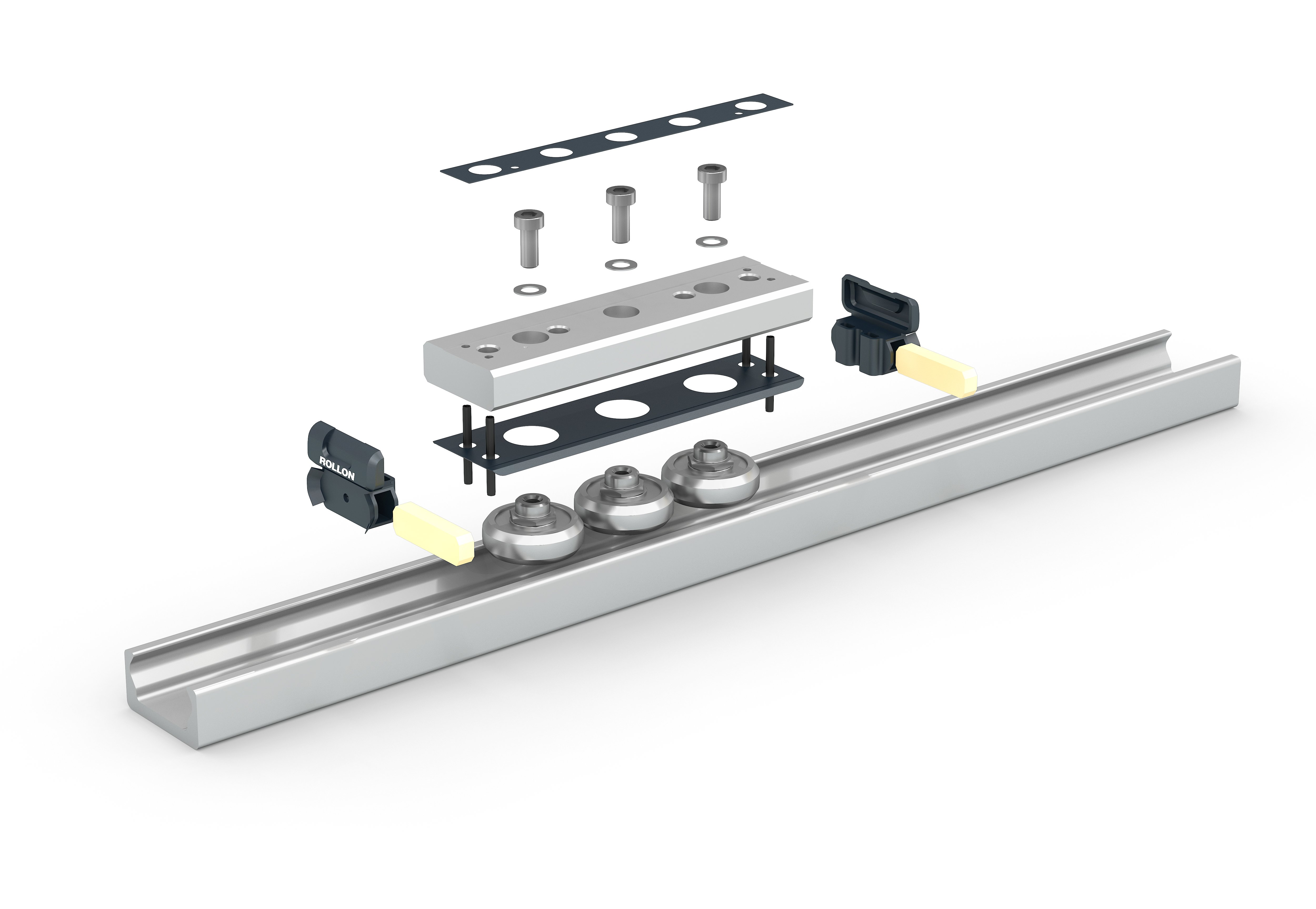

Luigi and his team chose Rollon Corporation's Compact Rail linear rail system, which stands out for its ease of installation and the system's ability to absorb positioning errors.

"Compact Rail has not only proven to be a better solution structurally, but is ideal for mobile installations, with frequent sliding of parts and exposure of the rails to misalignment."

"We simply attached the Compact Rail rails to the truck frame and a 3-bearing slider was perfectly capable of handling the 900-pound load. This solution allowed us to configure more than 3 square meters of extra space for the mobile hospital unit, something that, along with the price, convinced the customer."

According to Thomas Osygus, Regional Sales Manager for Rollon Corporation,

"Compact Rail is designed to ensure smooth movement regardless of the actual parallelism of the mounting surface, which is why it was the ideal solution for SPEVCO's specific application."

"In addition, Rollon has provided rail raceways within the Compact Rail product profile, a configuration that protects the raceway from damage and contaminants while allowing rail and slider mounting in areas with limited space. Spring preloaded wipers integrated into the headers and side slider seals make this rail the optimal choice for a vehicle potentially exposed to high contamination environments."

Learn more about Compact Rail solutions