In automated packaging environments, meeting aggressive throughput goals typically depends on your robot's mobility and speed. Here's how a Rollon actuator helped BAUSCH Advanced Technologies — a packaging equipment manufacturer for the pharmaceutical industry — create a robotic pick and place system, all while improving speed and range of motion to meet demanding requirements.

The company was building a system to move pressurized containers in its packaging operation. The system had to pick the containers from a conveyor belt and place them on a cart with cut-out holes so workers could transport the products to shipping. This vertically oriented seven-axis application used a Stäubli TX2-060 to move 2.75-pound containers a distance of close to five feet. BAUSCH considered using a six-axis robot with a longer reach for this automated process, but needed a less-expensive solution. In addition, the robot had to:

- Be Stäubli-manufactured.

- Offset 5.9 inches (150 millimeters) from the carriage plate.

- Complete its end-to-end stroke in 1.5 seconds.

- Survive a cycle rate of 20 cycles per minute for eight hours a day, 365 days a year for five years.

- Require minimal maintenance.

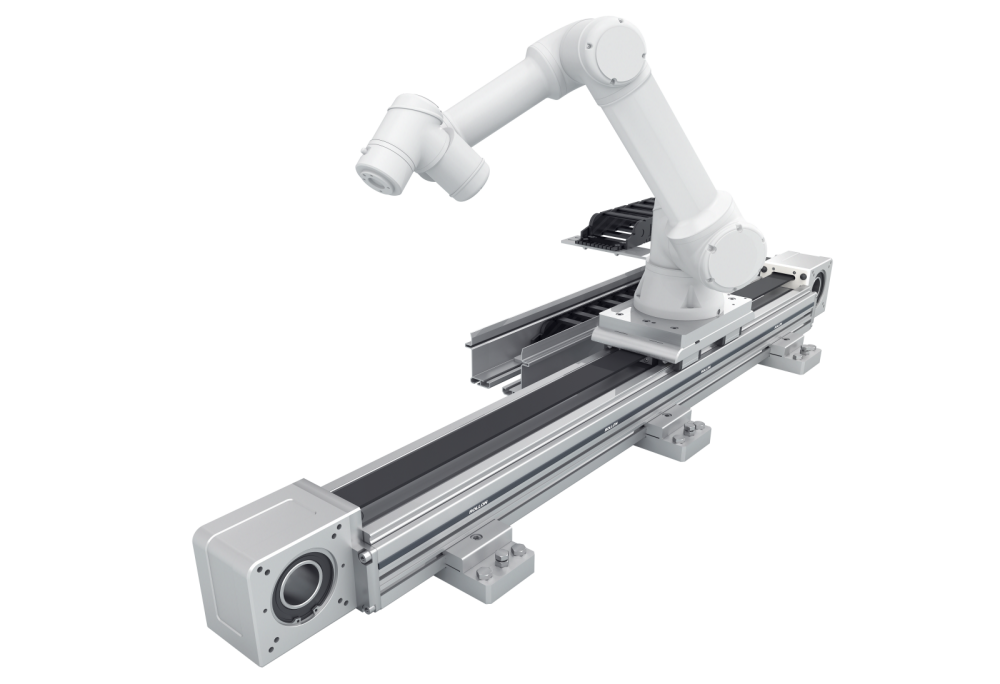

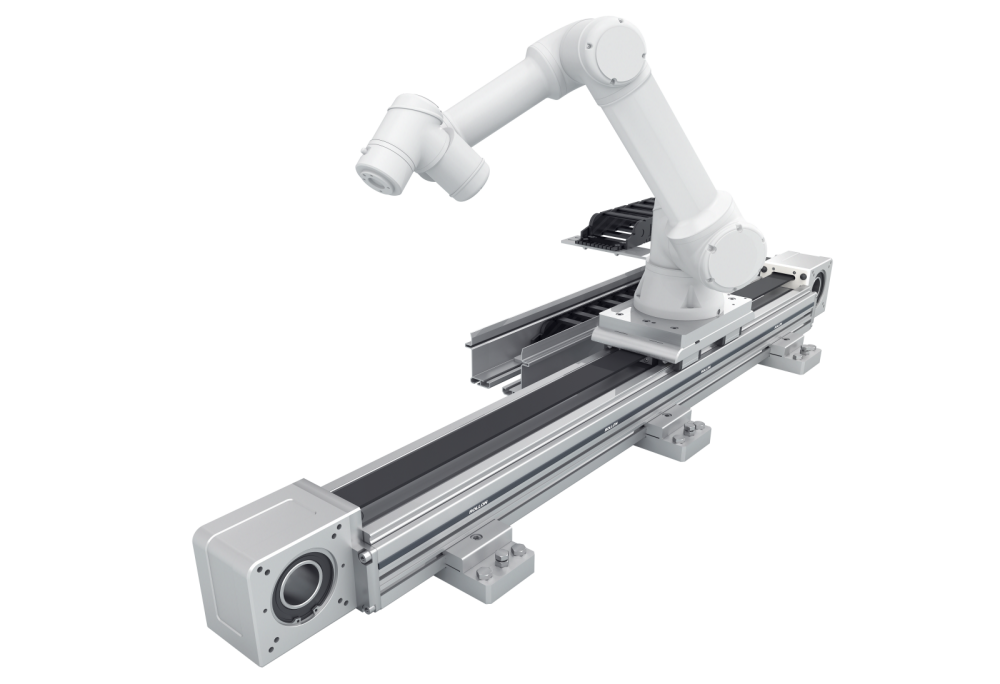

An Actuator With Robots and Cobots in Mind

The Rollon SEV220-1S was chosen to transport the Stäubli TX2-060. The SEV220-1S combines a high-quality reliable linear guide system and a single aluminum extrusion with a 220-millmeter width to achieve a greater moment of inertia. This proven, all-in-one solution for robot-on-rail includes a mounting plate that will accommodate a customer’s chosen robot — such as the Stäubli TX2-060 used in this application. It also comes with leveling feet, cable chain and carrier, and a gearbox to enable quick and easy installation.

Our SEV220-1S actuator allowed BAUSCH Advanced Technologies to quickly build a complete, mechanical axis system that met the speed and expanded work envelope requirements. Its compatibility with the Stäubli six-axis robot allowed the customer to further its partnership with Stäubli by implementing their robots at a U.S. facility.

Our experts can evaluate your needs and help you find the right Rollon Actuator Series axis for your automated operation.

For more information about Rollon actuators, visit our product page.