80,000 km of maintenance-free operation and a very low noise level: these are the main strengths of Rollon's Speedy Rail self-supporting linear rails.

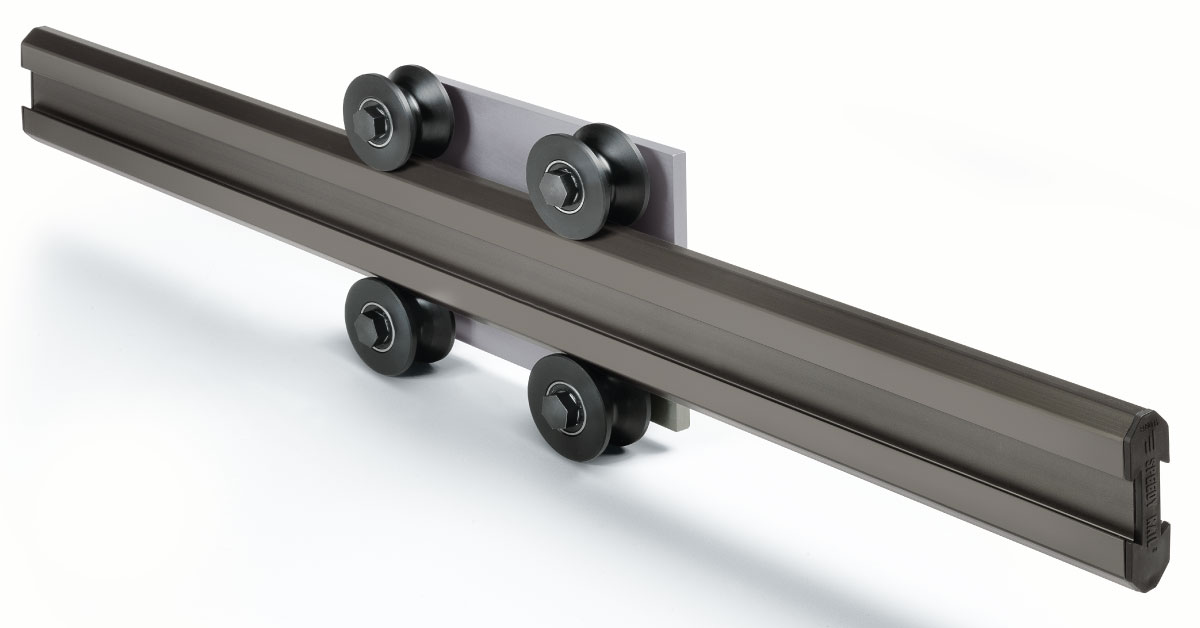

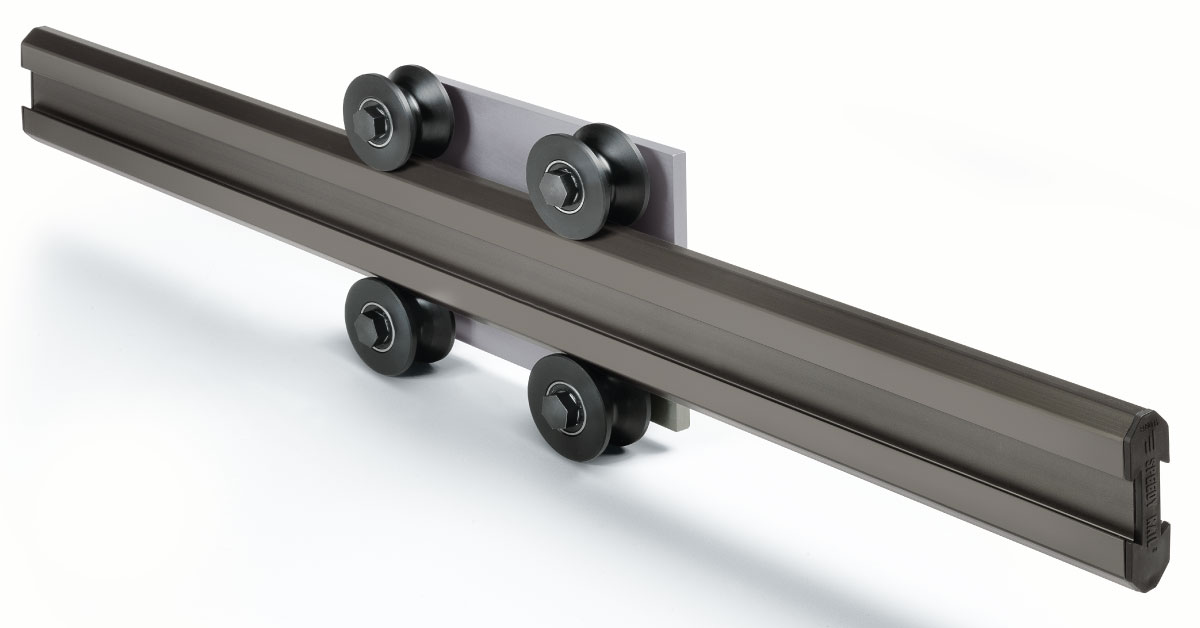

These are self-supporting and self-aligning rails composed of extruded aluminum profiles with deep hard anodization and steel bearings coated with plastic compound. These features, combined with the lifetime lubrication of the wheels with high-tech grease, make it possible to work up to 80,000 km without any maintenance. Speedy Rails also guarantee a high level of silence, in compliance with increasingly stringent laws and regulations that make noise a significant element in the analysis of production risks.

Quick to assemble and self-align

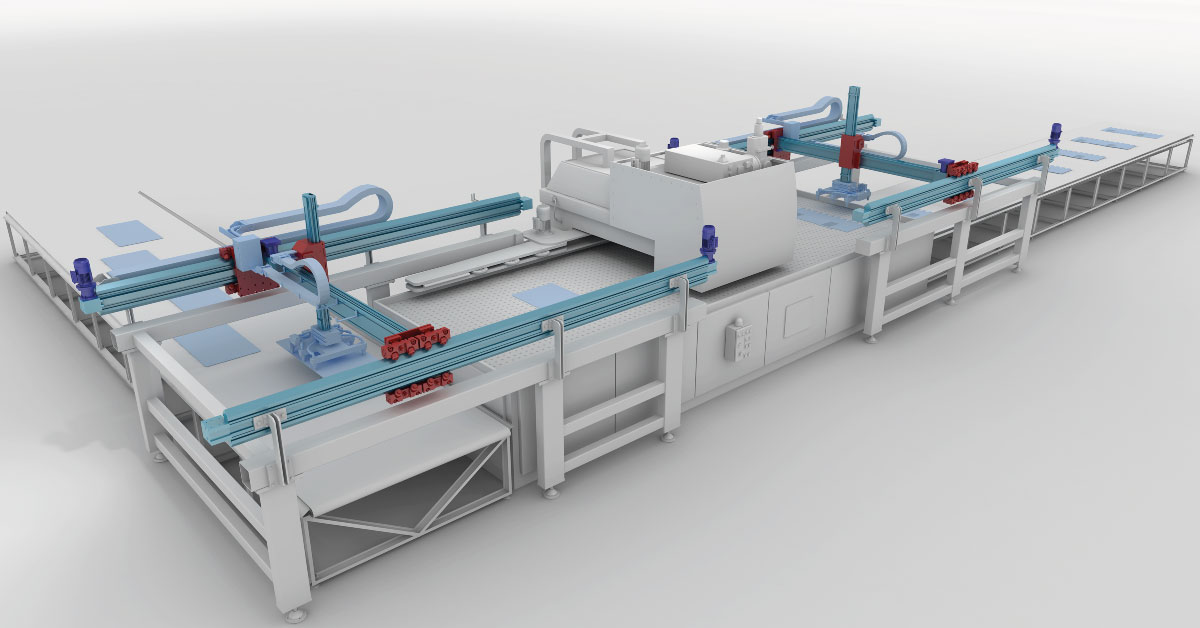

Strength, reliability and low noise go hand in hand with speed and simplicity of assembly: the rails are self-supporting and include in a single product the structure and the sliding system, so to mount them are sufficient limited support points without the need for structural work.

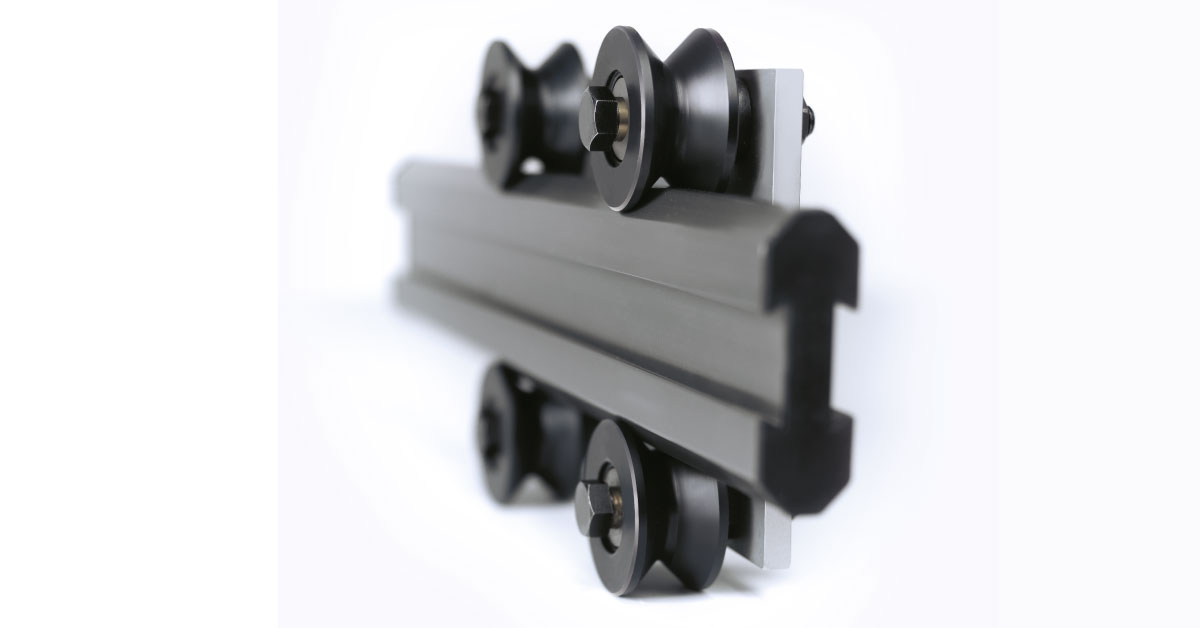

Moreover, simple joining kits are all that is necessary to ensure that the rails can withstand an unlimited number of strokes (these self-centering mechanisms have plates and dovetail joints). For parallel rails, the Speedy Rail rollers and supports are able to compensate for parallelism errors of up to 8 mm.

So much flexibility results in extremely fast installation, regardless of the production sector: an advantage that can generate significant cost savings. Speedy Rail guarantees high performance, with speeds up to 15 m/s and accelerations up to 10 m/s2. The product also offers a large load capacity, exceeding 3,000 kg for gantry configurations with 4 sliders to 8 casters.

They can be used as linear rails or actuators, and can be operated with a belt or rack and pinion drive. They are available with V type and cylindrical rollers, in five different sizes: 60, 90, 120, 180 and 250mm.

In addition to the loose components - rails, rollers and supports - with which the customer can build their own system independently, there is also a wide range of linear modules, both belt and rack and pinion, which can be customized if necessary.

Quick to assemble and self-align

Strength, reliability and low noise go hand in hand with speed and simplicity of assembly: the rails are self-supporting and include in a single product the structure and the sliding system, so to mount them are sufficient limited support points without the need for structural work.

Moreover, simple joining kits are all that is necessary to ensure that the rails can withstand an unlimited number of strokes (these self-centering mechanisms have plates and dovetail joints). For parallel rails, the Speedy Rail rollers and supports are able to compensate for parallelism errors of up to 8 mm. So much flexibility results in extremely fast installation, regardless of the production sector: an advantage that can generate significant cost savings.

Speedy Rail guarantees high performance, with speeds up to 15 m/s and accelerations up to 10 m/s2. The product also offers a large load capacity, exceeding 3,000 kg for gantry configurations with 4 sliders to 8 casters. They can be used as linear rails or actuators, and can be operated with a belt or rack and pinion drive. They are available with V type and cylindrical rollers, in five different sizes: 60, 90, 120, 180 and 250mm.

In addition to the loose components - rails, rollers and supports - with which the customer can build their own system independently, there is also a wide range of linear modules, both belt and rack and pinion, which can be customized if necessary.

Discover the most suitable rail for your application within the extensive Rollon range